STEEL

Every knife steel is a balance between three key properties: toughness (resistance to chipping or breaking), edge retention (how long it stays sharp under hard use), and stain resistance (how well it fights rust and corrosion). Most affordable steels let you max out one or two of the three; for example, carbon steels like 8670 is the toughest steel there is and holds an ok edge but will rust if you look at it wrong. A stainless steels like AEB-L keeps it’s toughness and rust resistance, but won’t hold an edge as long. If you want a steel that genuinely excels at all three—tough, scary-sharp for ages, and practically immune to rust—you’re stepping into premium territory (CPM-MagnaCut, etc.), and the price reflects it. Great performance always costs more when physics won’t let you cheat.

CPM Magnacut

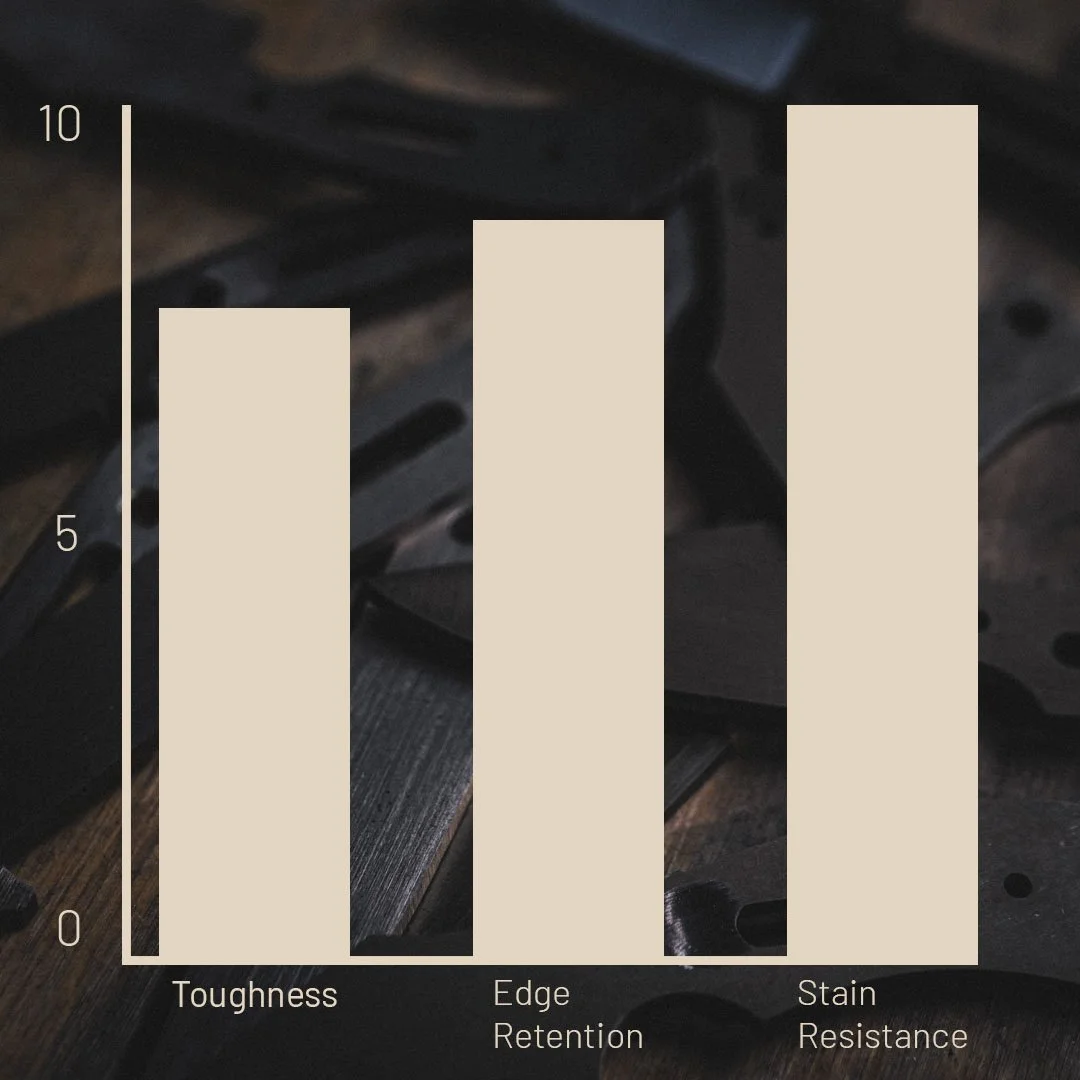

CPM-MagnaCut (made by Crucible Industries) is a “unicorn” steel because it’s one of the very few that legitimately hits elite levels in all three categories without a glaring weakness:

Toughness: Excellent — well above most other stainless steels and right up there with good non-stainless tool steels (think 4V or CruWear territory). It resists chipping and rolling even during heavy batoning or prying that would destroy lesser stainless blades.

Edge retention: Outstanding — it keeps a working edge longer than almost any other stainless and trades blows with top-tier non-stainless steels like S30V, M390, or even some of the higher-end powder steels when used for hard cutting/chopping. You’ll probably going to want diamond stones to sharpen this steel.

Stain resistance: Essentially fully stainless — better corrosion resistance than S30V/20CV/M390 and on par with steels like S45V. You can abuse it in wet, salty, or bloody conditions and it just laughs.

In short, MagnaCut is the rare steel that doesn’t force you to “pick two.” You get genuine top-tier performance across the board, which is exactly why it’s expensive and why almost every serious knife maker now has a MagnaCut model.

AEB-L Stainless

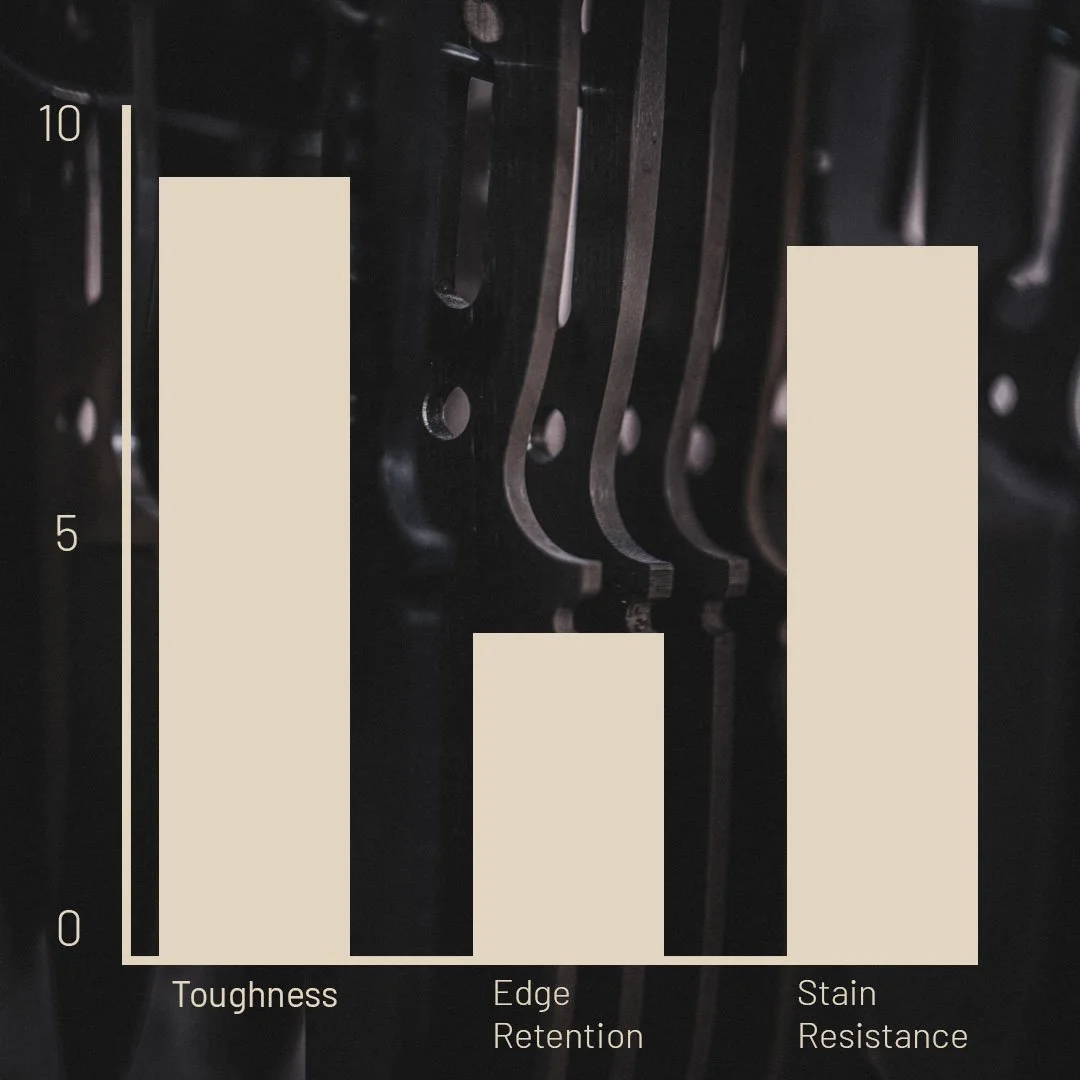

AEB-L (made by Sandvik) is a razor-blade steel that’s become a cult favorite in knives, especially for hard-use outdoors and kitchen blades. Here’s how it scores:

Toughness: Very good to excellent in thin, high-hardness grinds (60–63 HRC). It’s finer-grained than almost any other stainless, so it resists chipping extremely well behind a thin edge. It’s not quite as impact-tough 8670 in thick, heavy choppers, but is tougher than Magnacut. For bushcraft, and camp chores it’s one of the toughest stainless steels you can get.

Edge retention: Good. It stays “scary sharp” longer than basic steels, but it falls noticeably behind premium powder steels like MagnaCut, S30V, M390. You’ll touch it up more often, but it sharpens in seconds on almost anything.

Stain resistance: Excellent — basically fully stainless. It’s used in industrial food-processing blades and razor blades for a reason; you can leave it wet, bloody, or salty environments, and it barely pits.

Bottom line: AEB-L is the “toughness + stain resistance” pick that still takes a wicked edge and sharpens ridiculously easy. You give up some edge retention compared to the super-steels, but a lot of experienced users (especially in wet climates or for hunting/skinning) happily make that trade. It’s also quite a bit cheaper than MagnaCut while still punching way above its price.

8670 Carbon

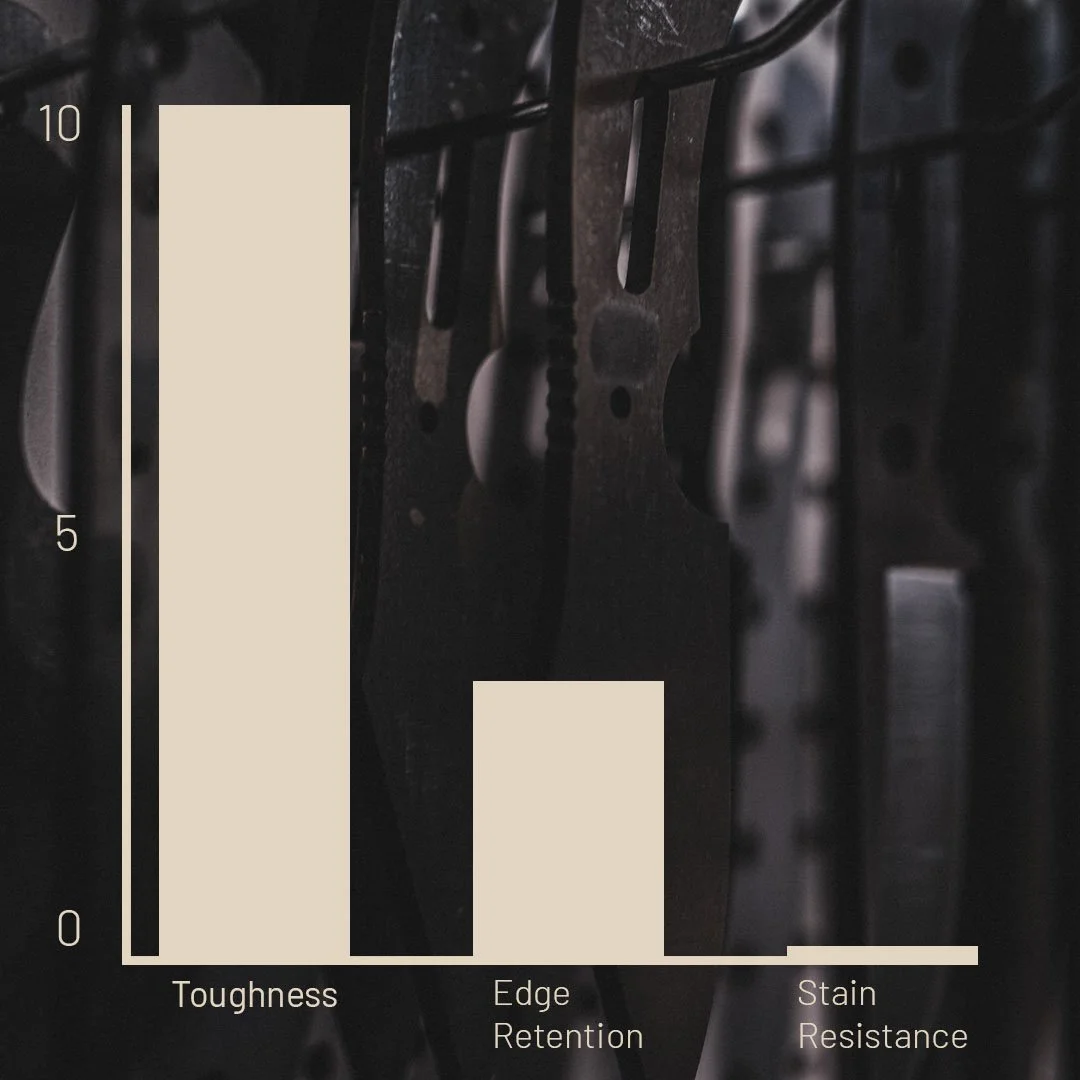

8670 is a classic American tool steel that’s gained a loyal following in hard-use bushcraft and survival knives. Here’s how it performs on the big three:

Toughness: Outstanding — one of the toughest knife steels you can buy, period. It’s a modified 5160 with nickel added for even greater impact resistance. You can baton through knots, pry when you shouldn’t, and chop hard all day without chipping or snapping. Very few steels beat it here.

Edge retention: Moderate — noticeably behind any super-steel and even behind AEB-L in long-term cutting tests. It dulls faster in abrasive or dirty conditions, but because it’s so tough, it will hold an excellent edge in clean wood-cutting/chopping tasks.

Stain resistance: Poor — it’s a carbon steel, so it will rust quickly if you don’t keep it oiled, waxed or forced-patinad. In wet or humid environments you’ll see spotting within hours after wiping it down unless you stay on top of maintenance.

Bottom line: 8670 is the toughness king for blades when you truly plan to beat the snot out of it and don’t mind some extra maintenance.

Shop Available Knives

-

The Woodsman

-

Woodsman Lt

-

Workman

-

Custom